With the rapid development of intelligent AI technology and the continuous improvement of people's quality of life, we have higher expectations for life health, food safety, environmental protection and other aspects, prompting related testing laboratories to put forward higher requirements in testing capabilities, safety, standardized management and other aspects. Today, laboratory institutions expect to use a complete set of laboratory information and intelligent management platforms to comprehensively optimize laboratory management, safety monitoring and hazard prevention, improve laboratory work efficiency and productivity, and improve laboratory quality management level, so as to achieve comprehensive integrated management of the laboratory's five core resources: "people, machines, materials, methods, and environment."

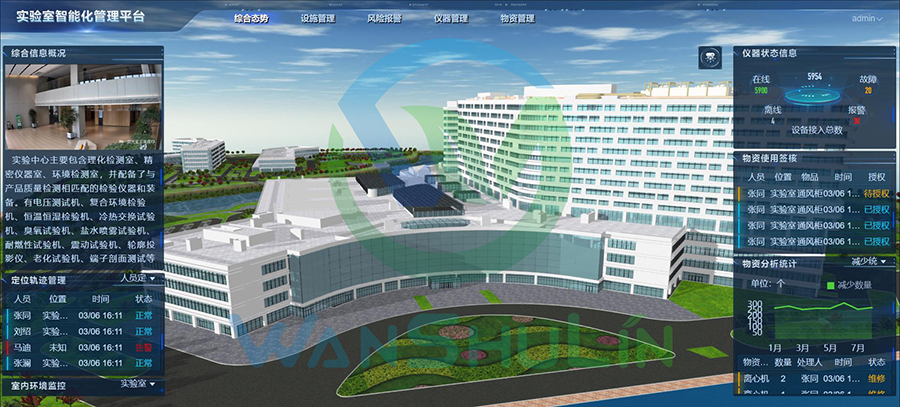

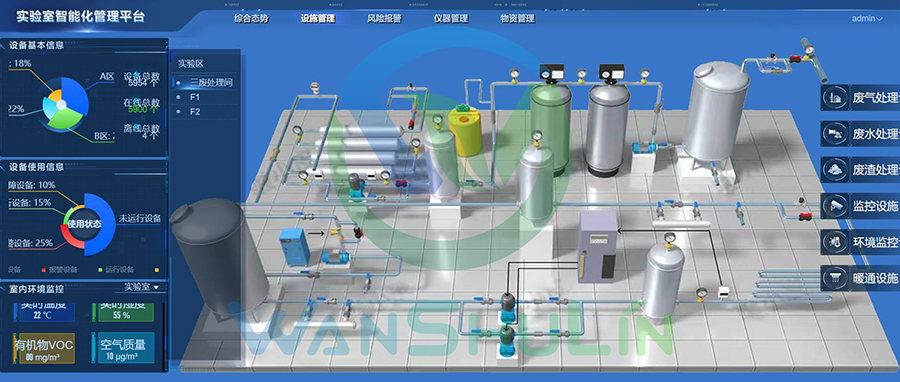

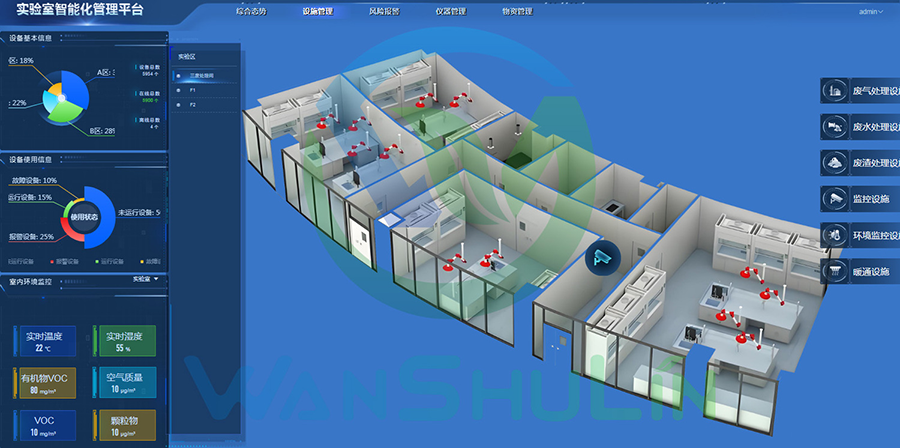

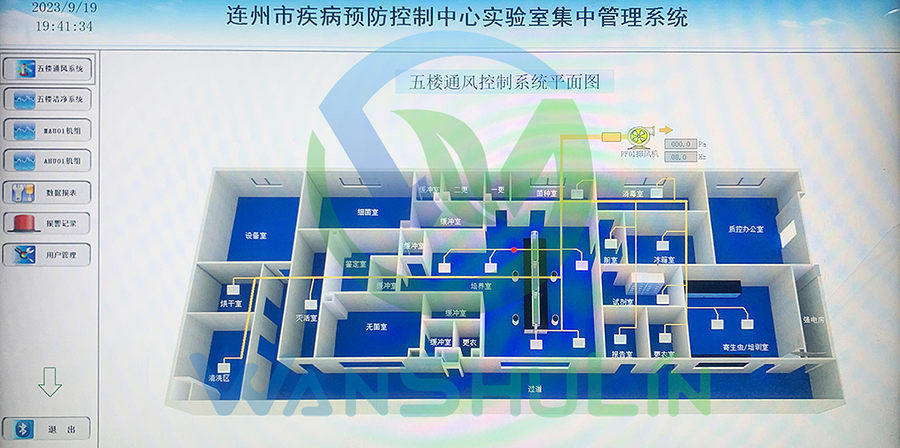

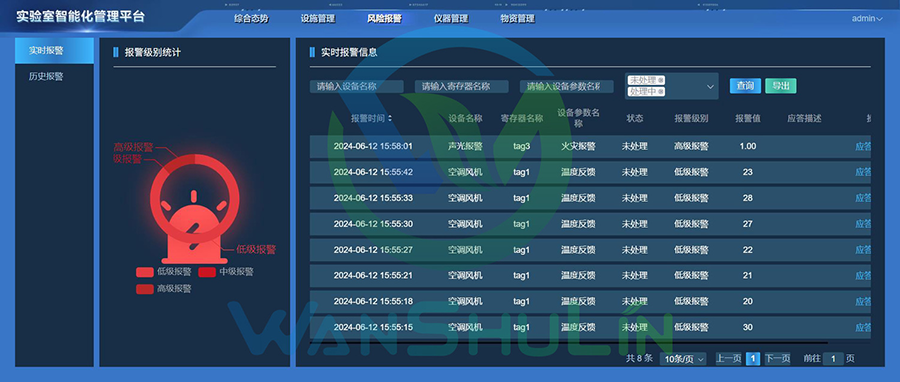

WanShulin Laboratory Intelligent Management Platform relies on technologies in the Internet of Things, cloud platforms, big data, etc., and through in-depth design and development of laboratory business and management, it combines laboratory equipment and hardware to create an advanced "Laboratory Intelligent Management WanS Platform" for laboratory users. The platform covers main modules such as HVAC intelligent management system, gas alarm system, instrument detection, process management, environmental monitoring, online services, data sharing, and project management.

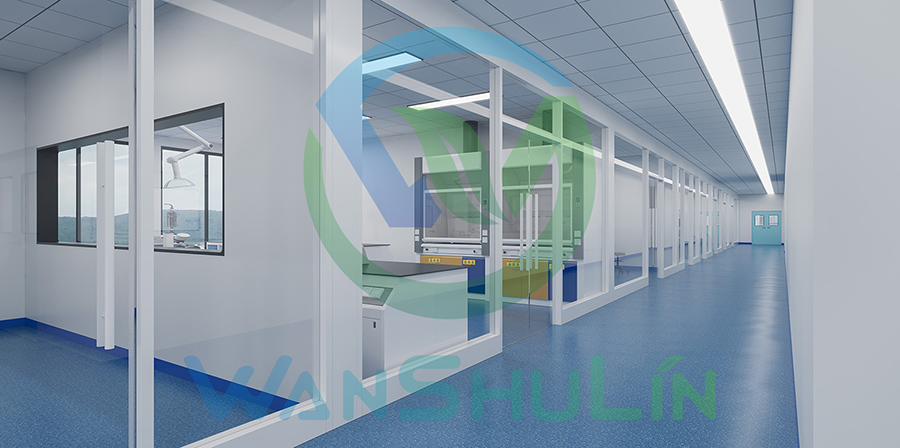

WanShulin's "WanS Smart Solution" consists of laboratory building layout and decoration system, air conditioning, ventilation, water supply and drainage, gas supply, electrical engineering, centralized safety monitoring system, laboratory furniture and supporting auxiliary equipment, user training, maintenance services, etc. It includes the entire process of comprehensive laboratory construction: from early planning and site selection, to the design and construction of internal systems, to system training and delivery, to later maintenance, etc. "Integrated laboratory" integrates the comprehensive capabilities of equipment suppliers, engineering contractors and service providers to ensure the safety and standardization of laboratory systems. Users do not need to consider too much about the details of the system, and all work is solved uniformly by the project's professional general contractor service provider.

The design and construction of Wanshulin's "smart laboratory" is based on relevant national standards and specifications, emphasizing on providing users with the most professional and complete system engineering. It integrates the equipment and functional requirements of laboratories at all levels. All disciplines follow a unified design and operating procedure, so that the final system is an organic whole, without causing the various parts of the system to be separated from each other, causing safety and operational risks.

With the improvement of our R&D capabilities and scientific and technological innovation, we have entered a new stage of intelligent construction of our modern laboratories in order to implement the innovation-driven development strategy.

With the rapid development of the life science industry, the laboratory field is facing many challenges while constantly innovating, such as the increasing demand for massive real-time data and advanced technical methods for popular technologies such as drug development and screening, gene sequencing, etc. clinical diagnosis requires faster and more accurate test results, laboratories pay more attention to the safety of personnel, etc. In the future, fully automated sample processing and testing platforms with advantages such as closedness, high intelligence, and high throughput are expected to gradually replace traditional automated pipetting platforms, amplification instruments and other automated equipment with limited standardization and integration. In the future, laboratories are rapidly developing towards high-throughput, large-scale, and comprehensive overall automation.

At present, foreign companies in the field of laboratory automation equipment are mainly in Europe and the United States, including Tecan, Hamilton, etc. These companies have first-mover advantages, and the scope of equipment extends from early biochemical, immunological, blood and other testing fields to the emerging multi-omics testing field, and they have a certain dominant position in the global market. In contrast, domestic laboratory automation equipment companies are under certain competitive pressure from foreign industry leaders. In addition, the supply chain of laboratory automation equipment is relatively long, involving cross-disciplinary patents and technologies, and some upstream components have not yet been localized, so domestic companies face great challenges.

The following are some specific examples of the application of smart laboratories in the field of testing:

• Medical testing: The Department of Laboratory Medicine of Beijing Tsinghua Chang Gung Hospital has built a smart demonstration laboratory. The fully automatic biochemical immunological assembly line can complete more than 100 test items including liver function, kidney function and a series of immune indicators. It is equipped with a single-tube pneumatic transmission system and robot sample transportation to realize the intelligent transmission and signing of outpatient samples. Through sample sharing, the number of blood collection tubes for patients will be effectively reduced. Manual operation steps will be reduced, potential biosafety incidents will be reduced, and the quality of the entire testing process will be improved. By optimizing the process, the waiting time for outpatient and emergency patients to get reports will be significantly shortened.

• Drug R&D: Jingtai Technology's independently developed intelligent automated laboratory uses artificial intelligence to assist in drug design and uses automated robots to replace traditional manual experimental operations. It includes key chemical and biological capabilities such as automated synthesis and automated crystallization. Its automated intelligent laboratory has flexible swinging robotic arms that intelligently perform steps such as adding materials and shaking, reacting and synthesizing the candidate new drug molecules predicted by AI step by step.

• Environmental monitoring: Jiangsu Provincial Environmental Monitoring Center improves its quality control system with the help of intelligent logistics comprehensive solutions, achieving the goal of intelligent, visual, and traceable closed management of samples in all links such as sample collection, temporary storage, circulation, sample retention, analysis, and statistics. The solution includes an integrated storage and delivery pneumatic transmission system, an integrated storage and delivery robot system, an integrated storage and delivery intensive warehouse system, and an integrated intelligent laboratory logistics management and control system, which effectively solves the management problems of transportation, handover, storage, and traceability during sample management.

• Food safety testing: To promote the standardized management of farmers' markets, establish and improve the food safety inspection and testing system, and establish a standardized and intelligent food safety rapid testing room. The rapid testing room can carry out testing of no less than 10 batches every day. The tested varieties basically cover the meat, vegetables, fruits, aquatic products, eggs, bean foods, on-site prepared and sold foods, bulk foods, etc. sold in farmers' markets. The main items tested are pesticide residues, veterinary drug residues, antibiotics, banned chemicals (sulfur dioxide, nitrite, hydrogen peroxide, formaldehyde, bleaching powder, borax), etc. The test results are announced to the public in real time through the smart display screen.